KELVINBRIDGE · GLASGOW

|TEL 0141 334 0557

BOOK NOW FOR IN-HOUSE ONE TO ONE OR VIRTUAL/REMOTE CONSULTATIONS

Jewellery design – creativity in CAD

- Date: 7th April 2020

- Author: Blair & Sheridan

- Categories:

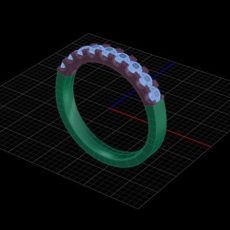

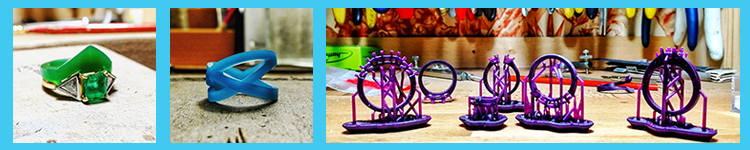

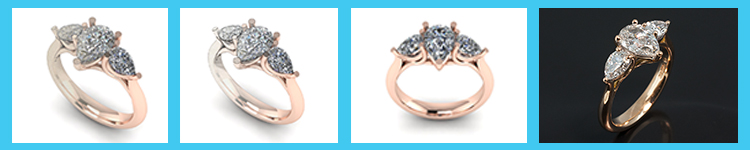

There’s no denying that computers and ever-changing technology have altered the landscape across industries – bespoke jewellery design is no exception. Combining the perfect mix of traditional crafting techniques and high-tech advancements can bring the most intricate designs to life. Utilising Computer Aided Design (CAD) and with the production of photographic realistic 2 dimensional images of a model / design we can give complete peace of mind to our customers prior to production. At Blair and Sheridan we can offer in-house 3d CAD jewellery design where a particular item requires it.

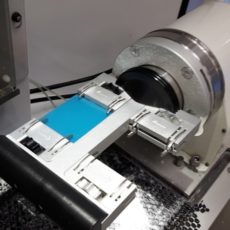

A combination of 3D printed and milled wax model ready for precious metal casting

Where does CAD come into the existing design process?:

Following a face to face design consultation (either in our showroom or remotely if required) with you to discuss ideas, agree budget, diamond/stone size (if applicable):

- One of our designers creates a sketch through your idea/picture for your consideration.

- Next stop, our talented CAD designer will create photo realistic renders or a 360° video for you to approve.

- If you are happy at this stage then work can begin on your finished design.

- The CAD model can be used to produce a 3D printed model in resin or a milled model in wax. This gives you an opportunity to see and try on the actual piece in a 3D form. All of these processes take place at our premises – therefore giving us consistency in quality and timescales.

From line drawing through the process of CAD drawing, view the 3D video simulation here

From here, the making of your design will progress into manufacture, again in-house by our experienced goldsmiths and stone setters.

Being able to design, CAD and craft all bespoke jewellery from our premises is what makes Blair and Sheridan so unique. We don’t rely on the logistics or timings of external suppliers giving us complete autonomy. The result is a truly bespoke and personalised service.

The complete CAD journey from drawing to milled wax model, piercing out

process and final cast item ready for stone setting

The gift of foresight

With the use of CAD we can extract the element of doubt offering a crystal clear representation therefore relying less on mental visualisation. Giving the opportunity to tweak the metal /stone / size etc. and see these alterations on screen you will have much better peace of mind prior to creation. From a production side, CAD generates definitive sizes and weights required for materials. This allows us to produce completely accurate quotes and minimise wastage in the production – a saving which we can pass on to the client. Even seemingly simple pieces of jewellery – perhaps an unusual size/shape/breadth – can be quoted precisely using a CAD drawing.

The final stages of CAD drawing are photo- realistic, final design (right), view the CAD video here

To summarise, the key benefits in Computer Aided Design in jewellery making means:

- Seamless process in the designing and making of bespoke jewellery designs

- More economical use of time and materials – less wastage and excess materials

- Working with you remotely is even easier as the drawings/video can be emailed to you if you cannot make it to the shop

With advancements in technology and communication it is possible to go through the entire design process remotely – you can make a virtual appointment with our design team here.

CATEGORIES

Archives

- February 2026

- October 2025

- June 2025

- April 2025

- March 2025

- December 2024

- November 2024

- August 2024

- June 2024

- May 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- August 2023

- June 2023

- April 2023

- February 2023

- December 2022

- August 2022

- July 2022

- May 2022

- April 2022

- January 2022

- November 2021

- September 2021

- June 2021

- April 2021

- November 2020

- August 2020

- April 2020

- March 2020

- February 2020

- January 2020

- May 2019

- March 2019

- October 2018

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- March 2016

- October 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

Recent Posts

- The Top 5 Myths About Bespoke Engagement Rings

- Bespoke wedding rings from Blair and Sheridan – your love story comes full circle

- Adding colour to our craft: introducing coloured diamonds and gemstones to your bespoke jewellery

- Bespoke diamond engagement rings don’t have to cost the earth…

- Planning your wedding – it’s all in the detail

CONTACT US

- Blair and Sheridan

- Bespoke Diamond Jewellers Glasgow

- 417 Great Western Road

- Kelvinbridge

- Glasgow G4 9JA

- T: 0141 334 0557

- E: info@blairandsheridan.co.uk

RECENT NEWS

- The Top 5 Myths About Bespoke Engagement Rings 26th February 2026

- Bespoke wedding rings from Blair and Sheridan – your love story comes full circle 7th October 2025

COPYRIGHT © 2018 BLAIR AND SHERIDAN | BESPOKE DIAMOND JEWELLERS GLASGOW, SCOTLAND SC 412681 VAT No. GB 131 6499 13 | Terms & Conditions | Privacy Policy | Contact Us